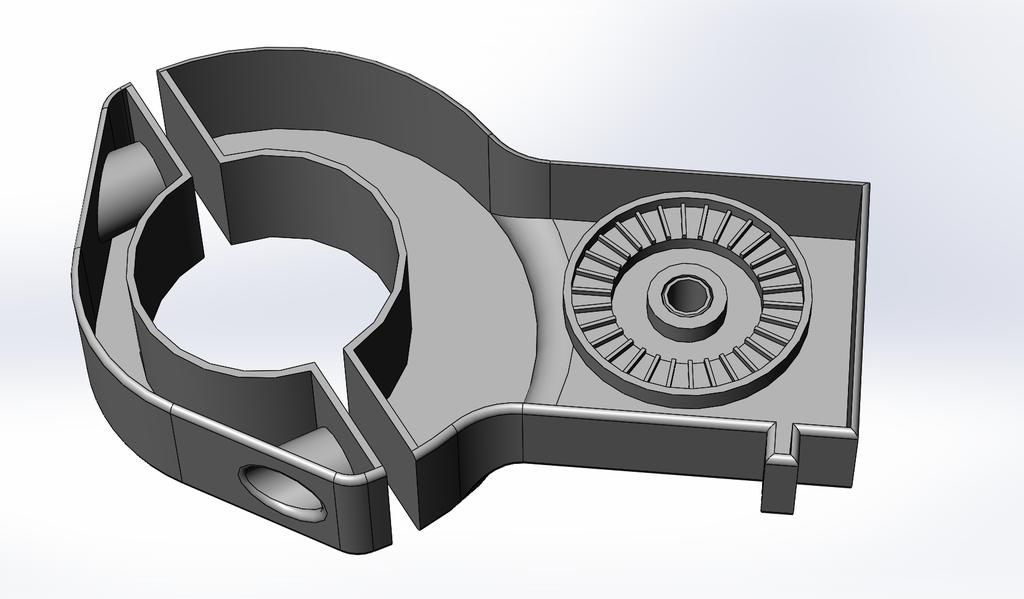

The Second Design

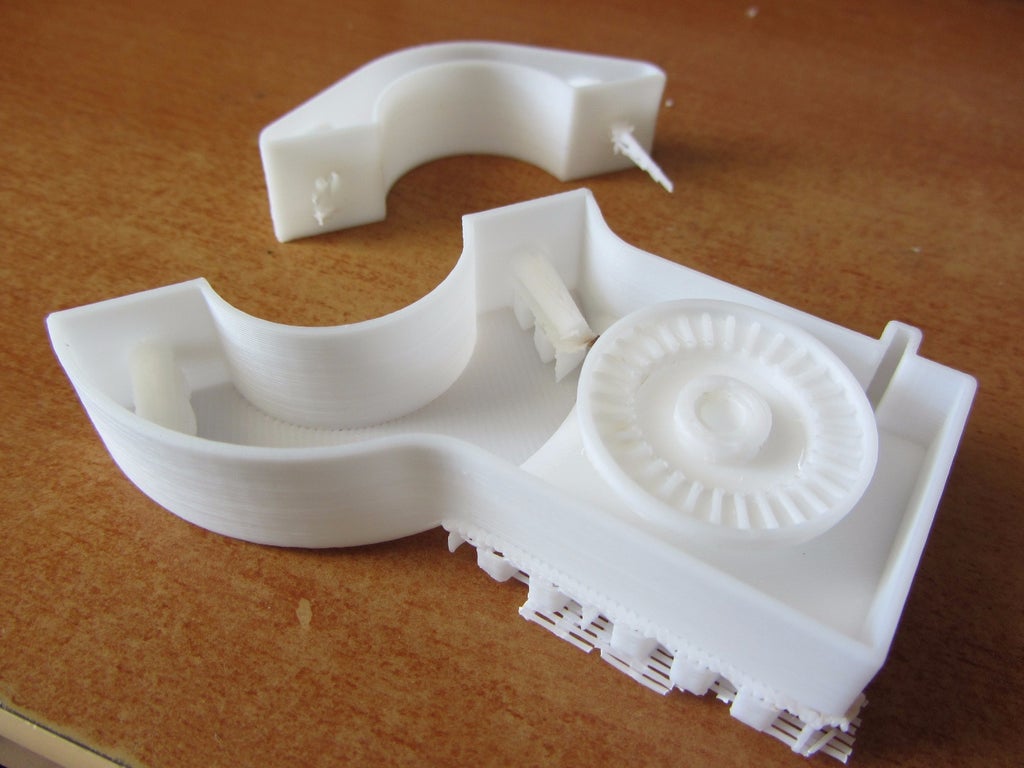

While making the first design, the idea was to partially fill the inside of the part with epoxy thru the extra holes drilled strengthening it from the outside by covering it with epoxy soaked fiberglass. While printing the first part, this second thought came to my mind to 3d model the part as a bare shell only and build the inside structure with epoxy and fiberglass later on.

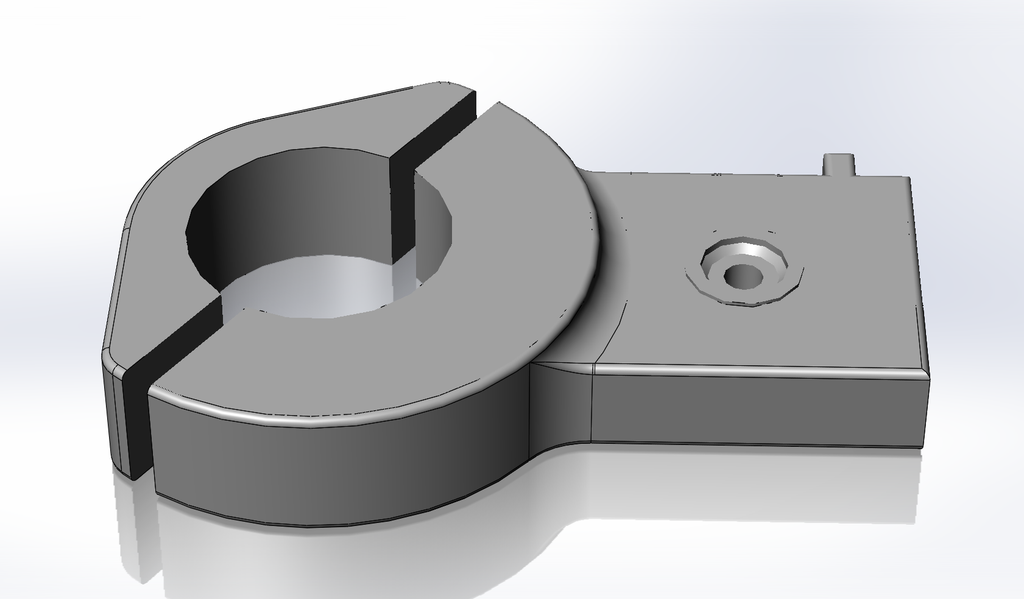

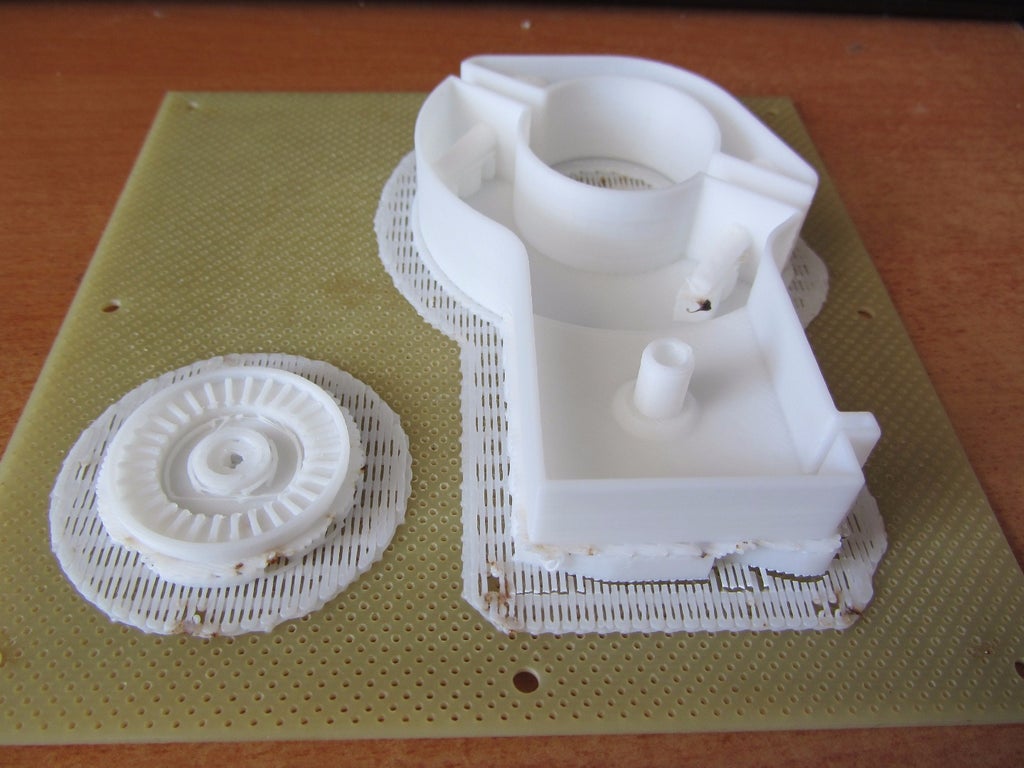

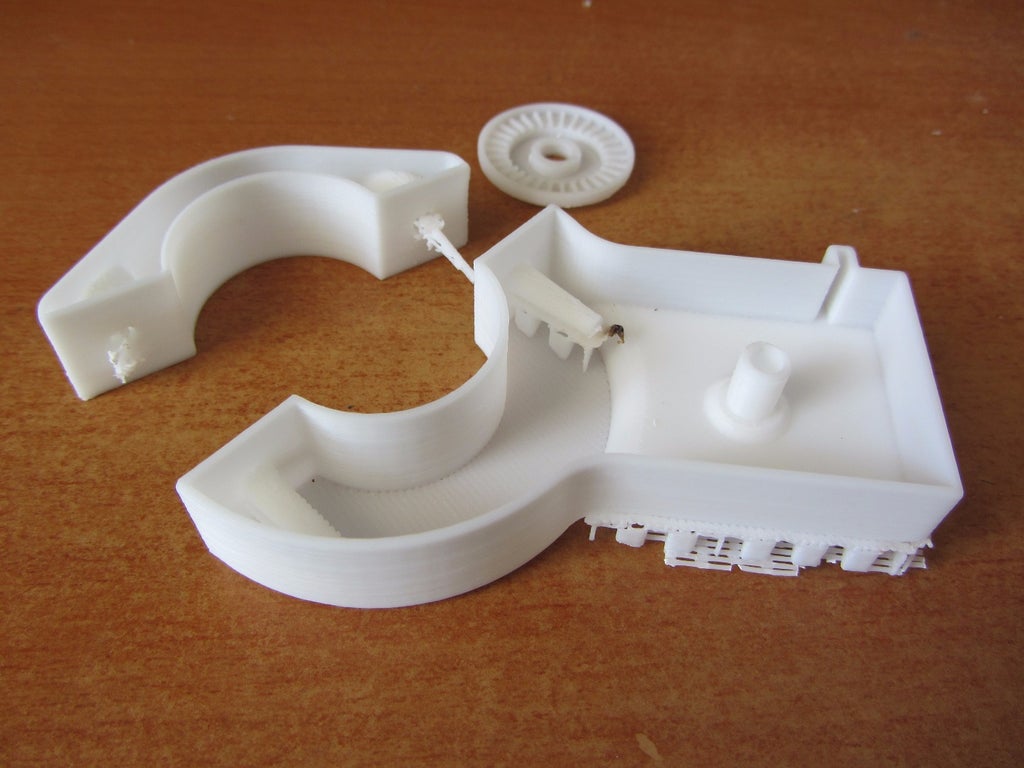

So I started modeling this while also still waiting for the layers of epoxy-fiber to cure over the first one. I wanted to manufacture both designs and compare them in strength and ease of production. I also used different approaches towards filling the part 1 and 2 of the second design( two parts were necessary for mounting the bag to the bike).

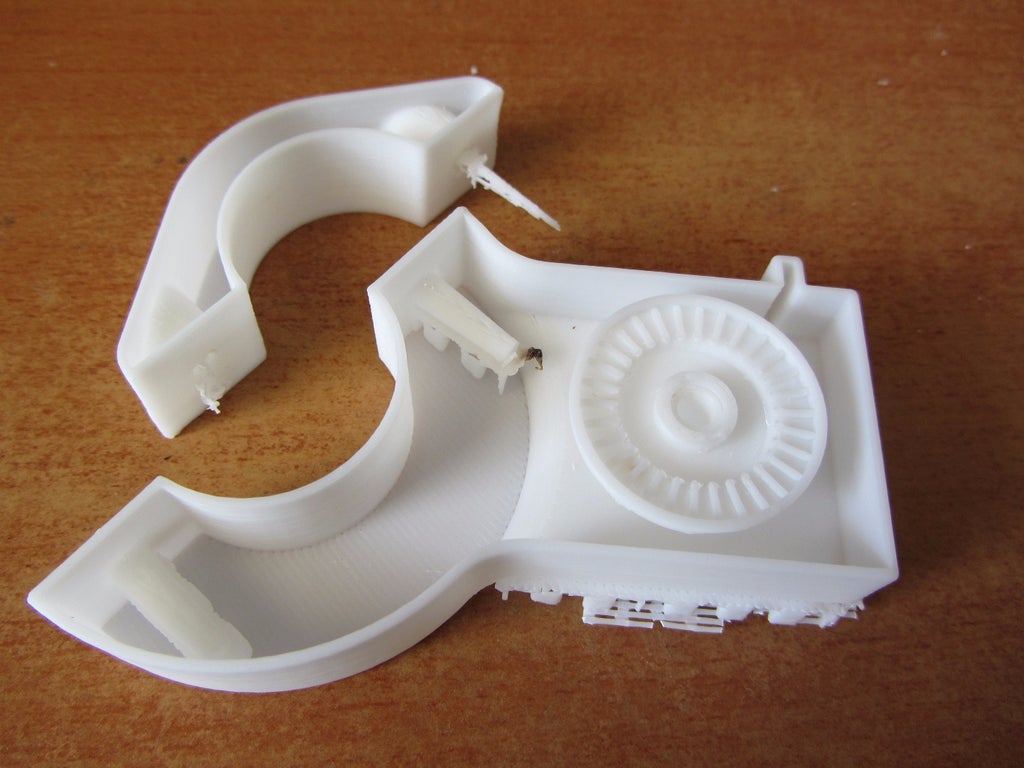

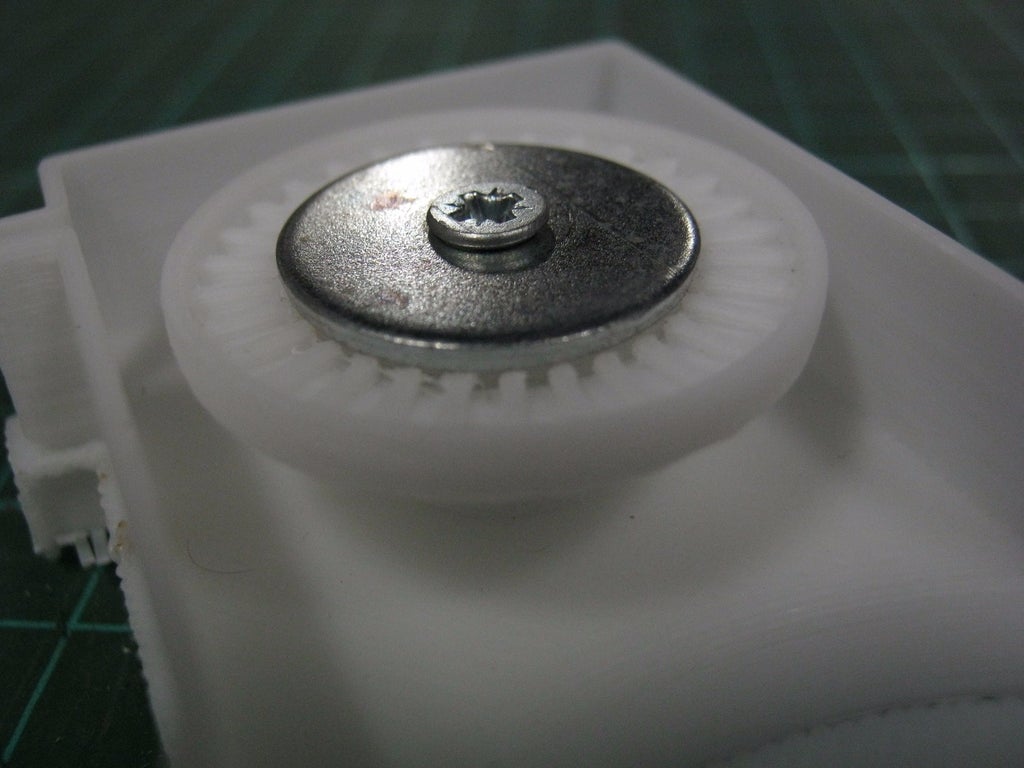

As seen, the second design is an empy shell with 1mm wall thickness. The round part is separated from the big part to make the filling process easier. It is possible to screw fit the round part back to the main part during the curing of the epoxy fill inside.

Users Today : 10

Users Today : 10 Users Yesterday : 112

Users Yesterday : 112 Users Last 7 days : 980

Users Last 7 days : 980 Views Today : 28

Views Today : 28 Views Yesterday : 233

Views Yesterday : 233 Views Last 7 days : 1731

Views Last 7 days : 1731 Total views : 1323628

Total views : 1323628 Who's Online : 0

Who's Online : 0